What is an Automatic Transfer Switch?

Everything You Ever Needed To Know About Transfer Switches

Transfer switches: What do they do? What types are there? What’s necessary for your project? Our full and comprehensive guide to literally everything you needed to know about transfer switches.

When it comes to generators, whether you’re an electrician, install generators for a living, or a DIY’er that just needs to get things done on a budget, chances are, you’ll be in the market for a transfer switch.

Now let’s fill in the gaps on the physics and fundamentals of these electrical control powerhouses.

In this article we’ll go over:

- What is a transfer switch?

- What do transfer switches do?

- What are the benefits of using transfer switches?

- What types of transfer switches are there?

- How to pick one that’s right for your application?

- And much more.

Keep reading to learn everything you ever wanted to know about these electrical commanders —which, we realize for some of you, may not be much! Having said that, if you’re someone who’s amped up about the idea of learning more, this piece is for you.

Warning: this article contains extensive use of acronyms. Best to keep a notebook handy to jot them down. Be forewarned.

Onto the article.

Transfer Switch Basics

The Canadian Electrical Code (CEC) defines a transfer switch as “actuates upon failure of the normal power supply, must control the emergency power supply.”

That doesn’t tell us much about transfer switches. Here’s our simpler, more helpful definition:

Transfer switches, also known as electrical switches, are the directors of the electrical world. They’re devices that automatically (or manually) transfer, or switch, from a primary power supply source to a backup source when there’s a power outage.

Phew! That’s better. With us so far? Good.

Now let’s define a transfer switch in more detail.

What is a transfer switch?

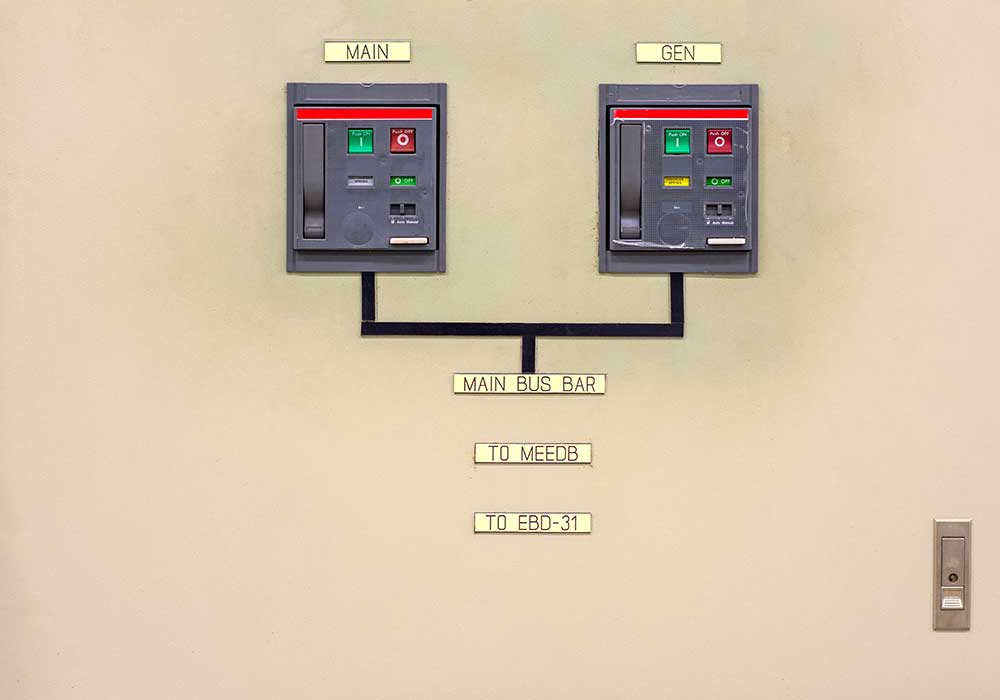

Transfer switches are devices that look like big metal boxes. More specifically (and seriously), these metal boxes are your building’s electrical supply controllers. They’re a bit like your home’s panelboard but they direct larger amounts of power.

What exactly does this mean, though? What do these switches do and how do they do it? Let’s find out.

What does a transfer switch do?

Transfer switches are used to redirect electrical circuits during a power outage. A transfer switch panel allows you to restore power, usually by using a generator, to critical circuits when utility power is no longer available. This ensures a near-continuous source of power for things like:

- Production lines and machinery

- Heating systems

- Fire alarm systems

- Industrial refrigeration

- Commercial air conditioning (AC) systems

Similarly, in a residential home, a transfer switch will transition electricity from the grid to a generator to power things like:

- Lights,

- Powerpoints (think a portable AC unit),

- A sump pump,

- Essential medical equipment (if applicable), and

- Hard-wired equipment like appliances (fridges, stoves), hot water systems, furnaces, etc.

Where can generator transfer switches be used?

Transfer switches are important parts of the electrical inner workings of:

- Farms

- Factories

- Data centres

- Hospitals

- Long-term care facilities

- Universities and schools

- Water treatment plants

- Organizations and small businesses, like restaurants

- Telecommunication facilities

- Electrical plants (ironically) and other types of power plants.

What happens when power to these buildings is lost? Mayday!

Thank goodness for transfer switches. They can use their powers to redirect electricity where it’s needed most. For example:

- Maintain life-support systems in a hospital,

- Keep livestock health and productive,

- Feed a solar or wind farm active in the event of poor weather

- Sustain freezers at a pharmaceutical manufacturing facility that store vaccines and medications.

What’s the source of these powers? More on this next.

What supplies power to a transfer switch?

Transfer switches would be useless metal boxes without a secondary energy supply. The source of that energy, or electricity, can come from:

- An electrical (or power) generator, or

- Other external device that feeds a current to the switch

When power goes out to a building, an electrical generator is told by a transfer switch, Hey—you’re on! It then feeds power to the building’s panelboard which it then sends to external devices.

A transfer switch can be installed indoors or out. It may look different depending on whether it’s powering a huge factory, school, or hospital but its main parts are the same.

We’ll cover those parts in another section.

Up next: we give examples of some of the major types of transfer switches.

What are the different types of transfer switches?

There are different brands like ASCO Power Technologies, Cummins Inc., and Thomson Power Systems but in general there are three different types of transfer switches:

- Automatic transfer switches (ATS)

- Manual transfer switches (MTS)

- Non-automatic transfer switches (NATS)

We’ll cover all three of those, plus some of their varieties. Let’s begin with one of the most popular types: the automatic transfer switch.

1 Automatic transfer switches (ATS)

As the name implies, Automatic Transfer Switches (ATS) do their thing automatically. Everything is done instinctively with this type of transfer switch.

When the power goes out, maybe only for a couple of seconds, the trusty transfer switch senses this and automatically tells the generator, “Quick! You’re on!” (Get it?) The switch then transfers the power source to your business or home from the electrical grid to the generator.

When the power comes back, the switch does its thing automatically again by disconnecting the power from the generator, transferring it back to the grid, and turning off the generator.

The automatic transfer switch then patiently waits for the next power outage so it can do its thing all over again.

Why you should use an Automatic Transfer Switch (ATS)

We weren’t being fair earlier when we called transfer switches metal boxes. Switches are important pieces of protective equipment that keep people, buildings, and the environment safe from:

- Freezing temperatures (due to loss of heat in a home or building)

- Power leaks

- Energy loss

- Lost capital

Where that last point is concerned, think about what happens when the power goes out at home. You scramble to save every piece of meat, fish, and other frozen items from your freezer box.

The same goes for stores, restaurants, offices, or public service buildings. Imagine the loss of money and the chaos a loss of power to a senior’s residence, a hospital, or a meat packing plant would cause. Transfer switches are an indispensable part of a building’s electrical system.

(We’re sorry, transfer switches, for any disrespect we may have shown you earlier in this post.)

To learn about the parts of an ATS, visit our website [https://www.primapowersys.com/].

Up next: we’ll cover one example of an ATS, the bypass isolation transfer switch.

Bypass isolation transfer switches

A bypass isolation transfer switch (BITS) is a type of ATS that comes with two switching mechanisms instead of one. This offers redundancy in emergency situations for critical uses.

In short, no pun intended, an ATS redirects electrical power to the system, while the BITS bypass acts as its backup.

BITS are used by:

- Healthcare centres

- Long-term care facilities

- Government institutions

- Power plants and other critical facilities

- Media companies and data centres

- For ATS testing or maintenance purposes

To top off this section on ATS’s, we’ll describe one last type of automatic switch: the service entrance-rated transfer switch.

Onto our second switch type on the list: manual transfer switch.

2 Manual transfer switches (MTS)

A Manual Transfer Switch (MTS) has to be, you guessed it, activated manually.

In the event of a power outage, a manual switch needs to be hand-operated by a real person in order to swap a building’s electrical grid to a backup power source. If no one is around to activate the switch, the power source isn’t reassigned and electricity stays off.

Not good if you have a hotel full of guests!

Not all manual switches are right for every application. How, then, can you ensure you’ve picked the right one in the event of a power emergency?

Answer: it’s all about how much phenomenal cosmic power a switch can handle. Read on to learn what we mean.

How to pick the perfect manual transfer switch

Have you ever blown a fuse? Not the emotional kind, the electrical kind. There was a voltage problem behind that cruel joke. Too much power went into the system and—Bam!—a fuse blows to protect it.

Similarly with switches, you’ll need the right device to handle the right amount of power. When picking a manual transfer switch, first:

- Determine the wattage you need to run your generator, then

- Pick a switch rated to that wattage (normally anywhere between 30 to 3,000 amps), and finally

- Choose a switch that has a built-in wattage metre (optional).

(A friendly note: Don’t despair if you don’t know what those electrical terms mean. We added them in to make us sound smarter. For those savvy readers who do, you’re welcome.)

And finally, we’ll introduce our third and final type of transfer switch: the nonautomatic transfer switch.

3 Non Automatic transfer switches (NTS)

At first glance, Non Automatic Transfer Switches (NTS) sound just like manual switches. Anything that isn’t automatic has to be done by hand, right?

Yes and no.

The term NTS is reserved for electrically operated switches.

- Like the manual versions, they’re incapable of self-initiating when there’s a power outage—they need human intervention to work.

- Unlike manual switches, they’re equipped with nifty electronic controls that manage everything about the power redirect once the main transfer has occurred.

These types of switches offer the following bonus features:

- They monitor power source characteristics like voltage and frequency

- They make sure power can only be moved over to a new source when all these specific characteristics are met—perfect in situations when a forced manual transfer is too risky.

- The ability to be controlled remotely.

The remote perk is perfect for situations where access to a physical switch is limited or dangerous to personnel.

Next up, we’ll cover the types of transfer switch transitions, or the ways in which they can switch between one power source to another.

What are the different types of transfer switch transitions?

What are transfer switches used for exactly? Sure, we’ve already established they’re in charge of redirecting a power when the main source fails but how do they do this exactly?

How does a transfer switch transition power from one piece of equipment to another?

There are two main ways:

- Open transitions, and

- Closed transitions

Keep reading for a breakdown of the differences between these ATS transition types.

Open transition transfer switches (OTTS)

Open transition transfer switches (OTTS) affectionately have what’s called a “break-before-make” switch function.

This means that:

- The transfer switch breaks the connection to the original, main power source …

- …before it makes a connection to the secondary power source first (usually to a generator) before switching off the connection with the utility source, and then

The flow of electricity is therefore interrupted for a split second.

Open transition switches are generally the most popular and affordable options out there because they’re generally compatible with the largest number of applications.

Closed transition transfer switches (CTTS)

In contrast, closed transition transfer switches (CTTS) work in the opposite way. They use a “make-before-break” switch function.

This means that:

- It makes a connection to the secondary power source first (usually to a generator) before switching off the connection with the utility source, and then

- Once it’s established it’s safe to do so, it breaks the connection to the original, main power source.

With these switches:

- Both the primary and secondary power sources (the utility and the backup/generator) are allowed to overlap briefly which …

- … avoids a momentary power loss that often goes along with OTTS systems.

Now that we’ve gone over the what, why, and how of transfer switches, let’s cover what’s in them.

What makes up a transfer switch?

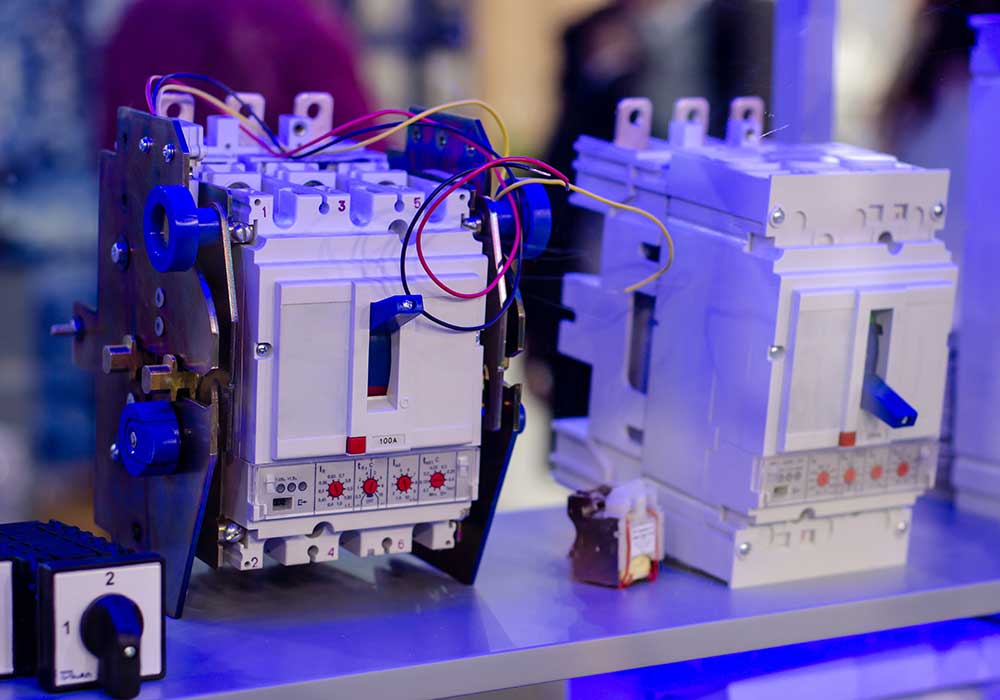

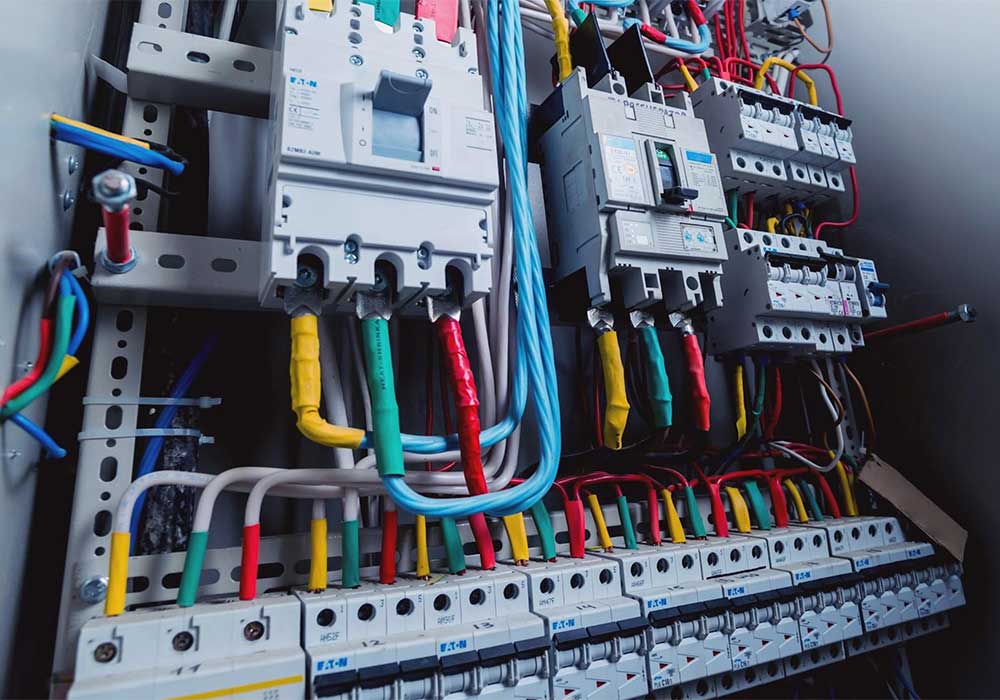

Transfer switches are made up of many fancy parts used to operate its inner workings.

A switch’s main components include:

- An enclosure

- The transfer mechanism

- Transfer logic controller

- A communications metre and instrumentation

Let’s go over each one of these in more detail next.

The transfer switch enclosure

The enclosure of a transfer switch is the metal skeleton that houses all its other parts. Remember the metal box we mentioned earlier? The frame is what we were talking about.

This part protects the inner workings from:

- The elements, if outdoors, and

- From regular wear-and-tear and other forms of damage (if indoors or out).

The size and configuration of the board depends on the number and load, or amount of energy, it has to power.

The transfer switch mechanism

The main structure of the board will house, among other things, the transfer switch mechanism

This is the rockstar part of the switch because it’s responsible for doing the power switching.

In most cases, transfer switches are mounted close to a wall for safety reasons. They’re more secure that way, plus electricians and technicians can more easily access their inner workings this way. A front facing board is the norm although there are exceptions depending on:

- Spacing,

- Maintenance needs, and

- Installation obstacles.

Do you know what’s at the front of a transfer switch that runs the switch mechanism? Controls. We cover these next.

Transfer logic controller

The transfer logic controller is an electronic controller that stores operating data, monitors the condition of the power sources, and initiates transfer sequences.

Along with the controller, there’s also a fancy spot on the front of the switch that provides information about what’s going on with the switch.

Read on to find out more about the communications metre.

Communications metre and instrumentation

Everything you need to control the phenomenal cosmic power (!) of a transfer switch is located on its front panel.

On the metre, you’ll find indicators that communicate any data an electrician or technician would want to know about the state and the workings of the switch.

Specifically, you’ll find information about:

- Power availability

- Potential indicators

- Voltmetres

- Malfunction gauges

- Energy usage displays

- And many other pretty lights and buttons in fancy colours.

Now that we know what makes up a transfer switch, let’s chat in more detail about the benefits of using them.

What are the benefits of using transfer switches?

Here are some of the main advantages to using transfer switches:

- Reliable and uninterrupted power supply

Transfer switches ensure you never lose power when your primary source of electricity is lost. That makes power reliable.

Downtime can be very costly. A loss of power could mean lost revenue when your business can’t stay open or from lost product.

Reliability means profitability and safety.

- Simple to use

Once an automatic transfer switch has been properly set up, you don’t need to worry about anything. It required a quick setup by a professional and will work for years.

- Safe to use

As much as a properly functioning transfer switch can save lives, it’s also equally safe to use.

Since there isn’t much to do after it’s set up, you can rest easy knowing your power supply will keep people safe during and inbetween power outages.

How to care for and maintain a transfer switch?

We might be biased but we’ll say it anyway: the best way to care for and maintain your transfer switches is by hiring a professional to do it for you.

As we hope we’ve demonstrated in this article, switches are complex pieces of equipment that manage a large amount of electricity. At the very least, a poorly maintained switch can mean a loss of power in an outage. While this isn’t always the worst thing in the world, it’s a nuisance.

At the worst, a poorly maintained switch can mean a loss of resources, money, and, in very extreme cases, serious accidents and even death.

Even a wish from a magic genie can’t protect you from a broken or poorly maintained transfer switch!

This isn’t the time for a DIY solution. Best leave the upkeep of your generators and switches to the pros. You, your assets, and those you depend on you to keep power flowing will thank you.

How do you know what type of transfer switch is best for you?

When it comes to maintaining power to a hospital, utilities plant, or other essential services building, now’s not the time to play a guessing game.

The easiest way to figure out which type of transfer switch to use for your residential or commercial building is to work with a professional.

A consult with a pro is well worth the investment. It can save you time, money, and frustration when it comes time to choosing and installing the right switch for your needs.

What about caring for your existing switches? Pros are the best option here, too.